Dust Collector

Micro dust collector (AMD-SERIES)

It is a product that removes fine dust of PM 2.5 (2.5 m or less) such as semiconductor device manufacturing process, soldering and dipping, clean room work, and ultrafine dust work.

| Model name | Wind volume (m3/min) |

Static pressure (mmAq) |

Output (Kw) |

Size | Weight (Kg) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| A(+a) | B | C | D | IN(Ø) | OUT(Ø) | |||||

| AMD-020 | 25 | 230 | 1.5 | 750 | 700 | 1500 | 1683 | 150 | 200 | 190 |

| AMD-030 | 40 | 230 | 2.2 | 800 | 820 | 1860 | 2063 | 200 | 250 | 240 |

| AMD-050 | 60 | 230 | 3.7 | 800(+390) | 820 | 1900 | 2128 | 250 | 300 | 270 |

| AMD-075 | 80 | 250 | 5.5 | 1450(+455) | 820 | 2000 | 2228 | 300 | 350 | 398 |

| AMD-100 | 100 | 250 | 7.5 | 1450(+480) | 820 | 2000 | 2228 | 350 | 400 | 465 |

We can manufacture various sizes with stock sizes (Inquiry: 82-31-494-8013)

-

three-stage filter

three-stage filter1. Primary PRE Filter - Remove dust with large particles of about 3 to 30 meters and capture 85% of dust

2. CFM Filter - Remove oil and adhesive dust and capture 65 to 95 percent dust of 1cm particles

3. HEPA Filter - Collects 99.7% or more dust of 0.3m particles

-

TURBO FAN Mounting

TURBO FAN Mounting1. Easy to disassemble/assemble, easy to maintain and operate 24 hours a day

2. High efficiency and premium motors are applied to reduce operating costs relative to long-term operating hours (for 3-phase motors)

3. low noise · low vibration · Extend motor life due to low temperature increase

-

Options

Options1. Filter differential pressure instrumentation (differential pressure gauge) - to display the time of derailment and replacement (analog/digital)

2. Change of dust emission method - Basic type: Drawer type dust box is detached and easy to recover dust

3. Pre-treatment flame cut-off device and explosion-proof structure change

-

Precautions

Precautions1. Not suitable for organic solvents and odors containing volatile and flammable substances.

2. Not suitable for large particles of dust generation.

Grinder integral type dust collector (AGD-SERIES)

This product removes fine dust of PM 2.5 (2.5 m or less) such as semiconductor device manufacturing process, soldering and dipping, clean room work, and ultrafine dust work.

| Model name | Wind volume (m3/min) |

Static pressure (mmAq) |

Output (Kw) |

Size | Weight (Kg) |

||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | OUT | |||||

| ACY-051 | 10 | 75 | 0.34 | 480 | 500 | 875 | 977 | 100 x 355 | 95 |

| ACY-030 | 10 | 75 | 0.34 | 480 | 500 | 910 | 1012 | 100 x 355 | 95 |

We can manufacture various sizes with stock sizes (Inquiry: 82-31-494-8013)

-

Grinder

GrinderThe head grinder is 100% domestic and has excellent performance and durability. A safety barrier and warcraft are fitted.

-

Cartridge filter

Cartridge filterProcess POLYESTER aftershocks into cartridges to increase filtration area and increase capture efficiency. Various types of contaminants can be applied with different filters (TEFLON, NANO, NOMEX, etc.).

-

Cartridge filter(SHAKING)

Cartridge filter(SHAKING)Manual thalli method(a fundamental form)

- The method is to shake the side dusting rod to dislodge the dust by vibrations.

-

OUTER ROTER FAN

OUTER ROTER FANAll-in-one fan features miniaturization and lightening. Compared to wind volume, low electricity consumption (high efficiency) is excellent.

-

Not suitable for high-oil dust work.

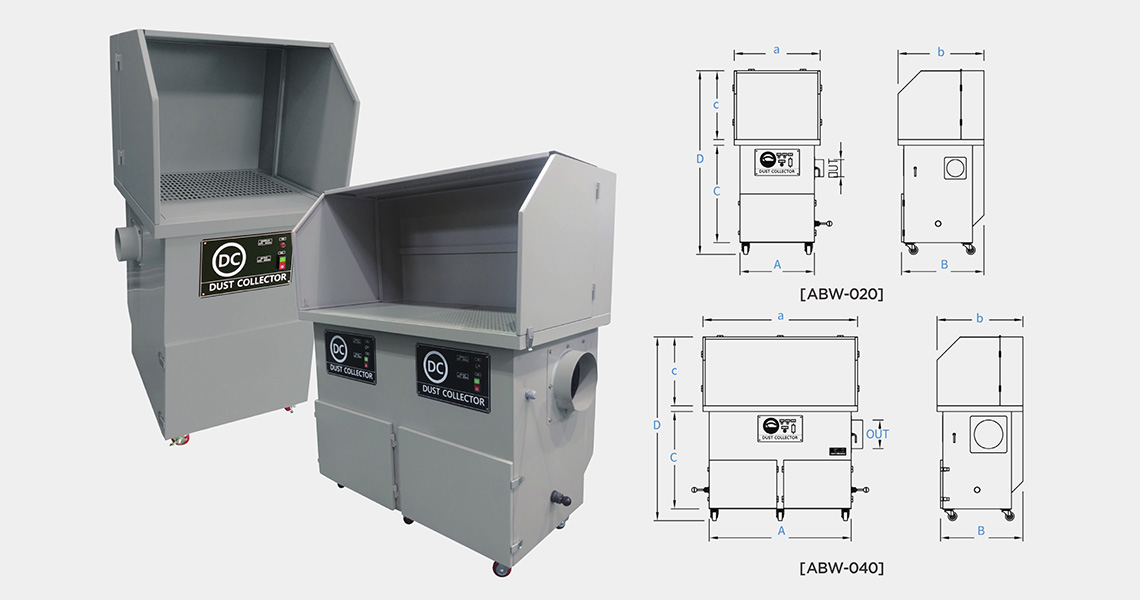

Workstation integral type dust collector

(AGD-SERIES)

It is a product that combines a workstation and a dust collector, such as grinding, sanding and thought, air washing, and measuring work, making it easy to work with and good at using space.

| Model name | wind volume (m3/min) |

Static pressure (mmAq) |

Output (Kw) |

Size | Weight (Kg) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | IN(Ø) | OUT(Ø) | |||||

| ACY-020 | 20 | 180 | 1.5 | 750 | 750 | 1500 | 1603 | 750 x 600 | 200 | 590 |

| ACY-040 | 40 | 180 | 1.5 x 2EA | 1350 | 750 | 1500 | 1603 | 1350 x 700 | 250 | 715 |

We can manufacture various sizes with stock sizes (Inquiry: 82-31-494-8013)

-

Workstation

Workstation1. The downward inhalation in the workstation hood prevents dust from scattering when working on it.

2. The upper left and right sides of the workbench can be opened and closed, allowing various sizes of workpieces.

-

TURBO FAN Mounting

TURBO FAN Mounting1. Easy to disassemble/assemble, easy to maintain and operate 24 hours a day

2. High efficiency and premium motors are applied to reduce operating costs relative to long-term operating hours (for 3-phase motors)

3. low noise · low vibration · Extend motor life due to low temperature increase

-

Cartridge filter(SHAKING)

Cartridge filter(SHAKING)Manual thalli method(a fundamental form)

- The method is to shake the side dusting rod to dislodge the dust by vibrations.

-

Bag filter

Bag filterThe filter area of the filter is wide and the dust collection efficiency is increased by using a square-plane backfilter.

-

Options

OptionsFilter differential pressure instrumentation (differential pressure gauge) - to display the time of derailment and replacement (analog/digital)

-

Precautions

PrecautionsNot suitable for high-oil dust work.

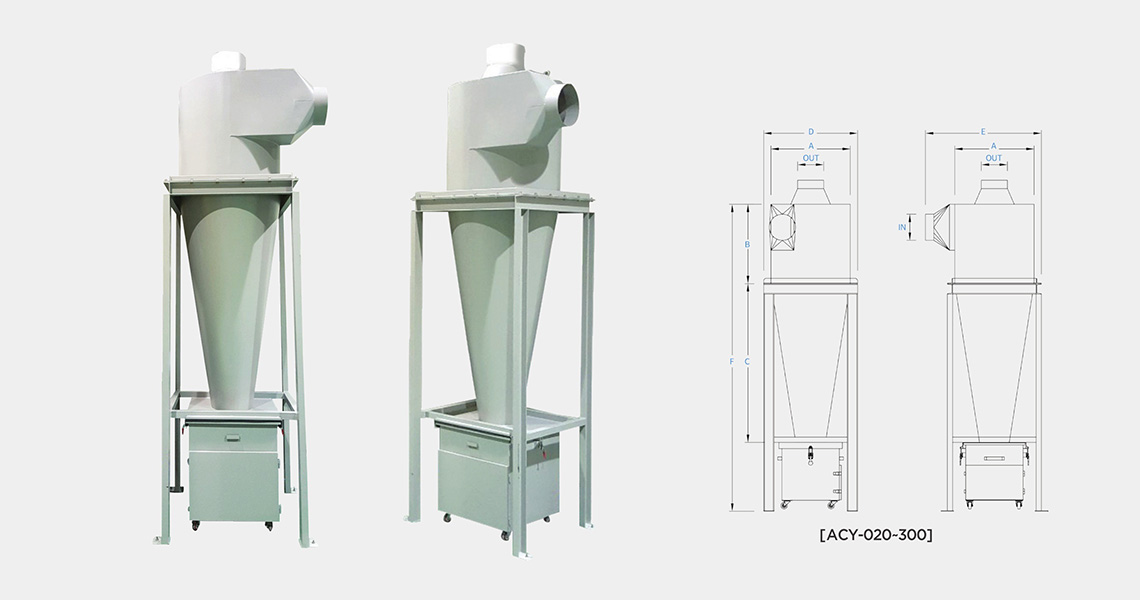

Cyclone dust collector (ACY-SERIES)

Effectively remove dust and moisture without filters using centrifugal force and gravity leaching principle.

| Model name | wind volume (m3/min) |

Size | Weight (Kg) |

||||

|---|---|---|---|---|---|---|---|

| A | B | C | IN(Ø) | OUT(Ø) | |||

| ACY-020 | 25 | 440 | 640 | 1960 | 150 | 150 | 65 |

| ACY-040 | 40 | 620 | 830 | 2580 | 200 | 200 | 120 |

| ACY-060 | 60 | 760 | 1040 | 3170 | 250 | 250 | 295 |

| ACY-060 | 60 | 760 | 1040 | 3170 | 250 | 250 | 295 |

| ACY-080 | 80 | 880 | 1180 | 3700 | 300 | 300 | 360 |

| ACY-100 | 100 | 980 | 1310 | 4030 | 350 | 350 | 520 |

| ACY-150 | 150 | 1200 | 1600 | 4960 | 400 | 400 | 597 |

| ACY-200 | 200 | 1380 | 1830 | 5650 | 500 | 500 | 645 |

| ACY-250 | 250 | 1540 | 1990 | 6130 | 550 | 550 | 695 |

| ACY-300 | 300 | 1680 | 2130 | 3550 | 600 | 600 | 720 |

We can manufacture various sizes with stock sizes (Inquiry: 82-31-494-8013)

-

cyclone dust collector feature

cyclone dust collector featureIt is a dust collector using the principle of cardiac and gravitational precipitation, and the larger the particles (10), the better the capture efficiency. It is generally available as a preprocessing device. Dust containing large amounts of dust and oil can also be removed, with a simple structure that is easy to maintain and free of charge. There is no filter, so there is no blockage caused by the filter and the suction power is maintained for a long time.

-

Options

OptionsMay change dust emission method

1) Basic type: The dustbox is detachable, making dust recovery easy.

2) Options : One-touch dust box (O/T), hopper (rotary valve/butterfly valve slidegate)

-

Precautions

PrecautionsSeparate power is required when used alone.

Odor-absorbing agent dust collector (AOD-SERIES)

It is a product that absorbs and removes odors and gases generated by low concentrations such as VOCS (Volatile Organic Compounds) generated in organic solvent industrial sites such as Odor-absorbing agent dust collector dust collector printing, paint painting, molding, cleaning and coating, drying, adhesion, raw material mixing, and air purification.

| Model name | wind volume (m3/min) |

Static pressure (mmAq) |

Output (Kw) |

Size | Weight (Kg) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | IN(Ø) | OUT(Ø) | |||||

| AOD-010 | 12 | 200 | 0.75 | 550 | 570 | 1100 | 1283 | 125 | 150 | 125 |

| AOD-020 | 25 | 230 | 1.5 | 680 | 700 | 1330 | 1513 | 150 | 200 | 175 |

| AOD-030 | 40 | 230 | 1.5 | 680 | 700 | 1330 | 1513 | 150 | 200 | 175 |

| AOD-050 | 60 | 230 | 3.7 | 850 | 820 | 1950 | 2178 | 250 | 300 | 342 |

| AOD-075 | 80 | 250 | 5.5 | 1600 | 820 | 2060 | 2288 | 300 | 350 | 680 |

| AOD-100 | 100 | 250 | 7.5 | 1600 | 820 | 2250 | 2478 | 350 | 400 | 745 |

We can manufacture various sizes with stock sizes (Inquiry: 82-31-494-8013)

-

three-stage filter

three-stage filter1. Primary PRE Filter - Remove dust with large particles of about 3 to 30 meters and capture 85% of dust

2. CFM Filter - Remove oil and adhesive dust and capture 65 to 95 percent dust of 1cm particles

3. HEPA Filter - Collects 99.7% or more dust of 0.3m particles

-

Options

OptionsFilter differential pressure instrumentation (differential pressure gauge) - to display the time of derailment and replacement (analog/digital)

-

Precautions

Precautions1. Not suitable for high temperatures and large amounts of flame.

2. Pre-treatment equipment is required when working with a large amount of dust.

3. This product is not suitable for environmental (standby) licensing.

Oaint booth dust collector

Coming soon

Laser plasma dust collector

Coming soon